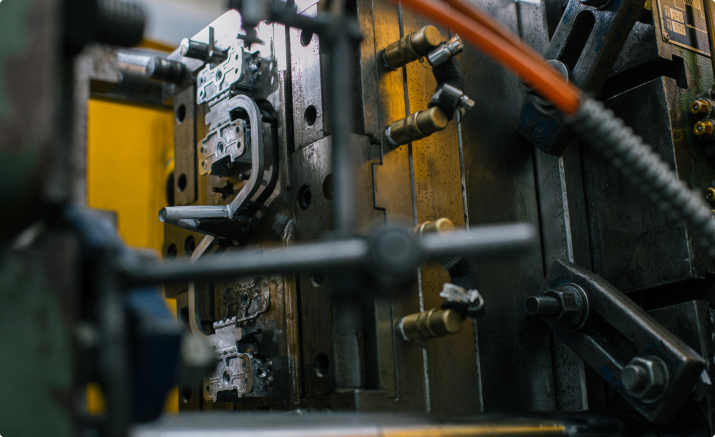

equipment

Description:

Max pressing (casting) weight – 1,1 kg. Max injection force – 65 кN.

HPDC

Zinc alloys, Aluminum alloys

Mold requirements:

Max plates size (distance between pillars) – 310х310 mm. Mold height: min – 120 mm; max – 340 mm.

casting machines’ features

Furniture fittings

Door fittings

Tools

Fastener

Toys

Electrical fittings

raw materials

Material

ZI0410 4.1 (ZAMAK5), AK9M2, AK8M3

Injection force

ZAMAK 65 кN, Aluminum

Maximum dimensions of molds (plates)

ZAMAK 310х310, Aluminum

Certificates

The quality is guaranteed by international certificates and spectral analyzes of each melt.

Alloys

ZL 0410 AK9M2 AK8M3.

Casting warranty 5 years

Applies to destruction and deformation in compliance with technical standards of operation.

Title of process step

Choose one of 3х options:

option 1.

customer has a mold

option 2.

customer has no mold, but has a sample

(physically, 3d layout)

option 3.

customer does not have a sample, but has a technical order

Title of process step

option 1.

customer has a mold

option 1

option 2.

customer has no mold, but has a sample

(physically, 3d layout)

option 2

option 3.

customer does not have a sample, but has a technical requirement

option 3

product prototype development

mold design

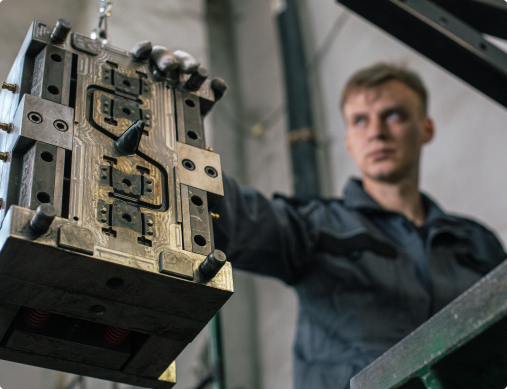

mold production

receiving the mold

mold inspection

approval of the finished product

casting

processing (tumbling / hydro-polishing)

package

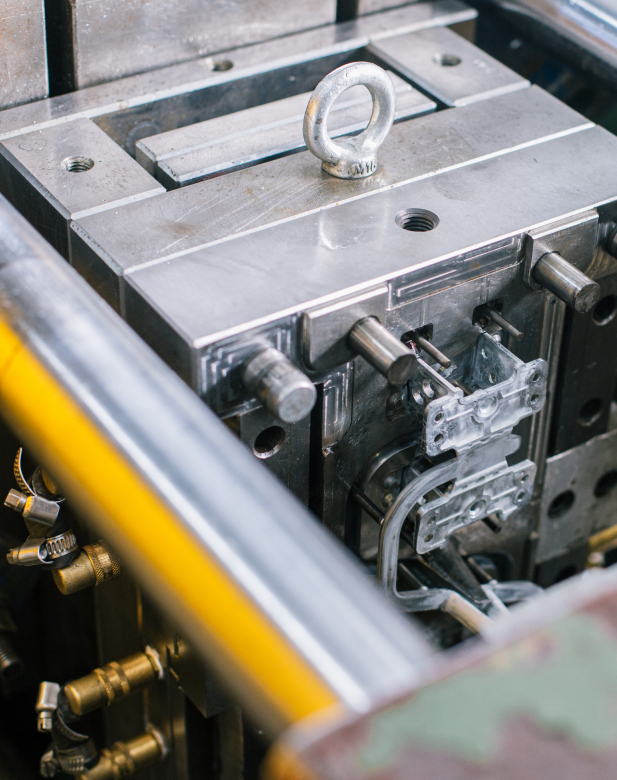

what is mold?

HPDC ZAMAK dimensions

Max size of mold plates – 310х310 mm.

Mold height: min – 120 мм; max – 340 мм.

Mold height: min – 120 мм; max – 340 мм.

technical requirement

Max casting weight – 1,1 kg.

materials

Using only heat-resistant steels "Böhler" (Austria).

PROPLASTICA accessories (Poland).

PROPLASTICA accessories (Poland).

We offer to develop a new mold

Mold – tool equipment for serial manufacturing of products made from metals, plastics, rubbers and other materials under the influence of pressure generated by casting machines.

why us?

ViVoTech

years

die-casting experience

machines

at foundry

thousand

of pieces per shift

Aluminum and zinc alloy casting

Own enginering department

Customer support 24/7

Fill in the form, please

Fill in the form, please

Fill in the form, please